Quality control inspection services by FBAHELP

FBAHELP performs quality control inspections of a wide range of products in China, including stainless steel cookware.

Stainless steel cookware QC inspection includes the following steps:

Checking for any manufacturing defects:

Deformation, pinholes, waviness, bad welding, uneven coating, loose handles, etc.

Checking for mechanical damage:

cracks, dents, scratches, chips.

After that the items undergo specific tests according to their intended usage. For example, induction cookware is checked for the following:

Material check.

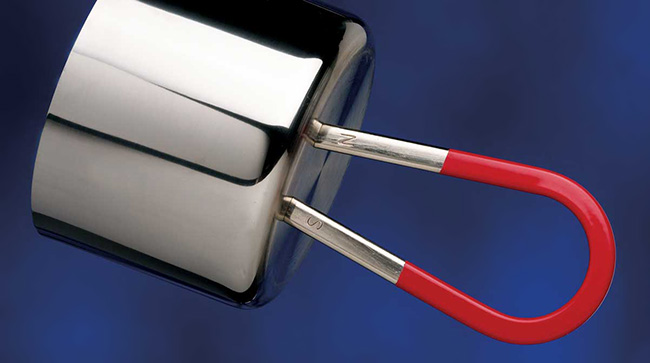

Pots and pans for induction cookers must be made of the appropriate material, because they are heated up by the magnetic field, created by the cooker. In order to verify that the inspector uses a magnet to check the ferromagnetic properties of the cookware. If the result is positive, the cookware can be used with induction cookers.

Measurements of the thickness and diameter of the bottom.

Deformation of the bottom is a common defect of induction cookware. In order to avoid that the thickness of the bottom must be between 0.07-0.2 inches, and the diameter – no less than 4.7 inches. Apart from taking measurements the inspector checks the smoothness of the surface, as any deformation has negative effect on thermal conductivity.

Special attention is paid to the handles and their thermal resistance properties. The inspector heats the item on a cooker for several minutes and checks the temperature of the handles.

More topics on Quality Control Inspection services

Pre-shipment inspection: relevant points

We would like to draw your attention to the following details concerning pre-shipment inspections. 1. Inspection request. We always do our best to arrange inspections promptly. In major production regions it is usually possible to organize an inspection next...

Factories vs reseller companies

How to tell a real factory from a trading company in China Reseller companies in China often present themselves as manufacturers. After receiving an order for production, they pass it to some factory, often being oriented towards the domestic market and having very...

AQL Standard in Quality Control inspections

Is AQL the most effective Quality Control method?AQL (Acceptance Quality Level) is a widely adopted Quality Control standard. It is used to determine how many units should be inspected and how many defects are acceptable during the inspection.The defects are usually...

How do we perform LIVE quality control inspection in China?

What is really happening at a Chinese factory? LIVE quality control inspection in China is an innovative service for Amazon FBA sellers. Check out our video to see how it’s done! Normally the client gets all the information about the inspection results...

Pre-shipment inspection in China

Types of defects and sample size The nature of potential defects and the percentage of inspected items There are basically three main methods of producing goods in China: automated partially automated manual manufacturing The production method determines...