Quality control inspection services by FBAHELP

FBAHELP performs quality control inspections of a wide range of products in China, including stainless steel cookware.

Stainless steel cookware QC inspection includes the following steps:

Checking for any manufacturing defects:

Deformation, pinholes, waviness, bad welding, uneven coating, loose handles, etc.

Checking for mechanical damage:

cracks, dents, scratches, chips.

After that the items undergo specific tests according to their intended usage. For example, induction cookware is checked for the following:

Material check.

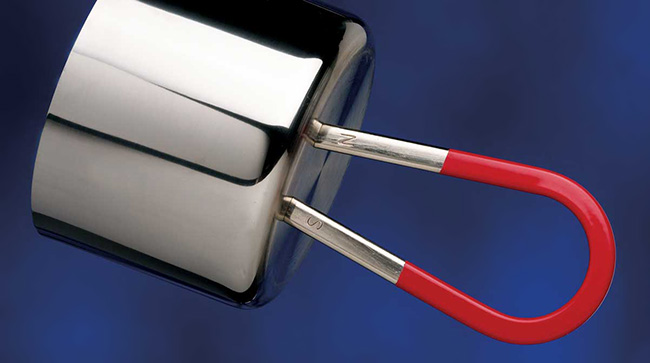

Pots and pans for induction cookers must be made of the appropriate material, because they are heated up by the magnetic field, created by the cooker. In order to verify that the inspector uses a magnet to check the ferromagnetic properties of the cookware. If the result is positive, the cookware can be used with induction cookers.

Measurements of the thickness and diameter of the bottom.

Deformation of the bottom is a common defect of induction cookware. In order to avoid that the thickness of the bottom must be between 0.07-0.2 inches, and the diameter – no less than 4.7 inches. Apart from taking measurements the inspector checks the smoothness of the surface, as any deformation has negative effect on thermal conductivity.

Special attention is paid to the handles and their thermal resistance properties. The inspector heats the item on a cooker for several minutes and checks the temperature of the handles.

More topics on Quality Control Inspection services

LIVE pre-shipment inspection for Amazon FBA

Quality control in China FBAHELP is proud to introduce an innovative service for Amazon FBA sellers – providing pre-shipment inspections in China in LIVE format. This approach is a true know-how in quality control services, taking them to a whole new...

Quality control inspections in China

Pre-shipment factory inspection framework Upon receiving the request for pre-shipment inspection, we coordinate the time of our arrival at the factory with you and the supplier. We suggest to perform quality control inspections in China after the goods are ready for...

Pre-shipment inspection in China

Quality Control inspections in China Pre-shipment inspection Constant quality control is the basis of successful business with Chinese suppliers. Lack of attention to this fact can easily result in losses because of partially or fully defective batch. Flawed items,...

Types of quality control inspections

Product quality control inspection in China In general, there are 5 types of quality control inspections: Factory audit. Pre-Production inspection. Mid-production inspection. Pre-shipment inspection. Container Loading inspection. Factory audit Factory audit is an...

Who pays for samples?

Who pays for the samples? Quite often Chinese suppliers expect you to pay for the samples. It is true that so called suppliers, trying to sell you something by pretending it to be a sample are quite common in Chinese internet space. Nevertheless, it is...