Quality control services by FBAHELP

Kitchen knives inspection procedure has certain specific features.

The major attention is given to the following points:

- Blade polish quality, texture and color homogeneity.

- Sharpness of the blade, absence of any defects on the cutting edge (chips, notches).

- Toughness and ductility of the blade.

- Handle quality, absence of any chips, cracks and other defects.

- Fitting of the handle to the blade: the handle should not be loose or flexible.

- Quality and strength of the packaging to prevent any damage during transportation.

Blade sharpness is checked experimentally, by cutting some products (usually tomatoes). In order to check blade toughness and ductility the inspector tries to bend the blade.

Ceramic knives are inspected in a similar way, apart from the bending test due to the fragile nature of the blade.

Inspection of expensive and specialized knives also includes the following checks:

- Hardness of the steel.

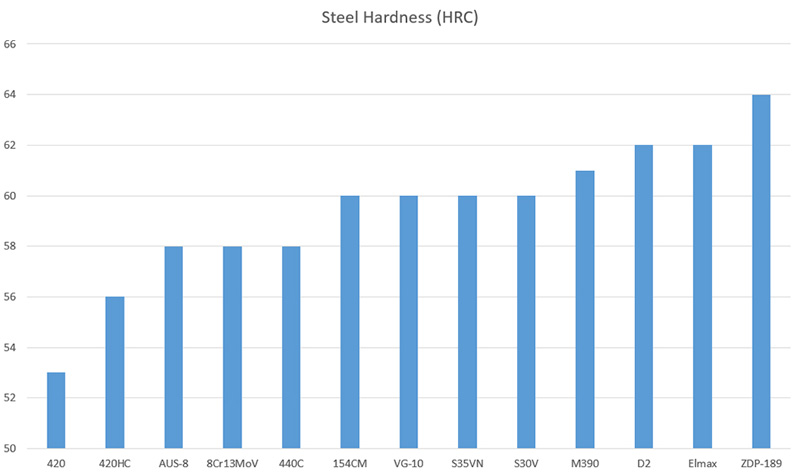

Steel hardness is measured on a Rockwell scale and must be stated in the accompanying documents for the knife. Kitchen knives hardness typically ranges between 45-60 HRC.

- Knife balance check.

- Laser sharpening.

In order to verify that the knife is laser sharpened the inspector checks the blade for specific visual cues – there must be perpendicular matte marks on the cutting edge.

More topics on Quality Control Inspection services

Supplier audit in China

The importance of a supplier audit in China Supplier audit in China is the best way to assess capabilities of a manufacturer before placing an order. When self-searching for suppliers in China on Alibaba, 1688, etc., you can only rely on the information, stated in the...

Quality control inspection in China for Ecommerce

Quality control in China: organisation details Quality control inspection is the best possible way to make sure that the quality of your product meets your expectations. The goal is to find defects and avoid their recurrence in future orders. Pre-shipment inspection...

Japanese quality at a Chinese factory: how to achieve it?

How can Japanese problem solving concept benefit your private-label brand? Once upon a time there lived a man, whose name was Fujio Cho and who had one peculiar habit. He was the head of an enterprise, but in the mornings he could usually be found at the shop floor,...

Furniture quality control in China

Checklist for furniture quality control inspection in China Furniture items must meet the highest standards in terms of build quality and aesthetics due to everyday use. Being afraid to “lose Face”, Chinese suppliers tend not to notify the client about problems or...

Quality control for Amazon sellers: Direct communication with the inspector

Quality control LIVE: Interact with a professional inspector, don’t read a boring report We perform all Quality Control inspections for Amazon sellers in LIVE mode, enabling direct communication between the client and the inspector. What problems do most Amazon...