Quality control services by FBAHELP

Kitchen knives inspection procedure has certain specific features.

The major attention is given to the following points:

- Blade polish quality, texture and color homogeneity.

- Sharpness of the blade, absence of any defects on the cutting edge (chips, notches).

- Toughness and ductility of the blade.

- Handle quality, absence of any chips, cracks and other defects.

- Fitting of the handle to the blade: the handle should not be loose or flexible.

- Quality and strength of the packaging to prevent any damage during transportation.

Blade sharpness is checked experimentally, by cutting some products (usually tomatoes). In order to check blade toughness and ductility the inspector tries to bend the blade.

Ceramic knives are inspected in a similar way, apart from the bending test due to the fragile nature of the blade.

Inspection of expensive and specialized knives also includes the following checks:

- Hardness of the steel.

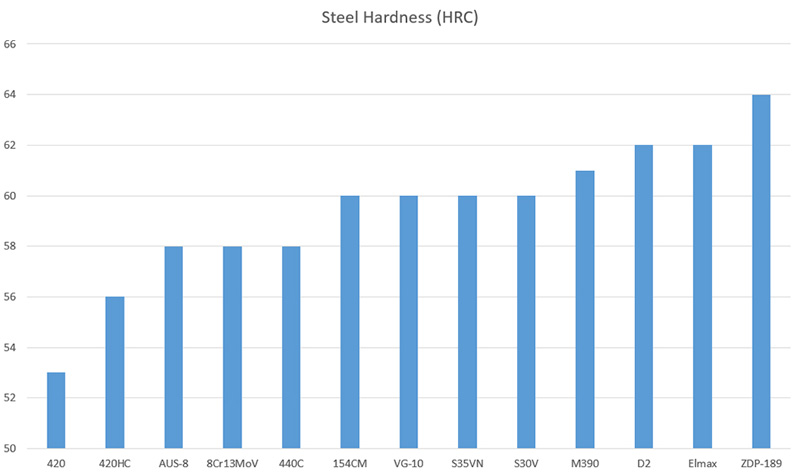

Steel hardness is measured on a Rockwell scale and must be stated in the accompanying documents for the knife. Kitchen knives hardness typically ranges between 45-60 HRC.

- Knife balance check.

- Laser sharpening.

In order to verify that the knife is laser sharpened the inspector checks the blade for specific visual cues – there must be perpendicular matte marks on the cutting edge.

More topics on Quality Control Inspection services

Packaging requirements for Amazon FBA

Amazon Packaging Requirements for FBA Sellers Thousands of merchants on Amazon use FBA – it’s Amazon’s state of the art fulfillment network which streamlines the selling process and makes selling a lot easier and more efficient for many sellers. For a small monthly...

Live product inspection by FBAHELP

Over the past two years we have conducted more than 2000 inspections in China, India, South Korea and Thailand and we have worked out highly effective quality control method. All our inspectors are foreigners, fluent in 2-3 languages, with permanent...