Types of defects and sample size

The nature of potential defects and the percentage of inspected items

There are basically three main methods of producing goods in China:

- automated

- partially automated

- manual manufacturing

The production method determines the nature of potential defects.

Automated manufacturing

All items in the batch usually have similar quality, because they are produced under identical conditions and on the same equipment. The only exception would be some malfunction or faulty operation of the machinery, leading to certain systematic defects.

If such production flaws are identified among the inspected samples, a certain percentage of items it the batch would have it as well.

This statement is also true for the opposite situation: if the inspected samples do not have any production defects, the rest of the items would also be fine.

Therefore, the inspection of 50-80 items from the batch is generally enough to draw a conclusion about the overall quality of the goods.

Partially automated and manual manufacturing

The use of manual labor increases the risks of various random defects due to human errors, especially in the absence of thorough internal quality control at the factory.

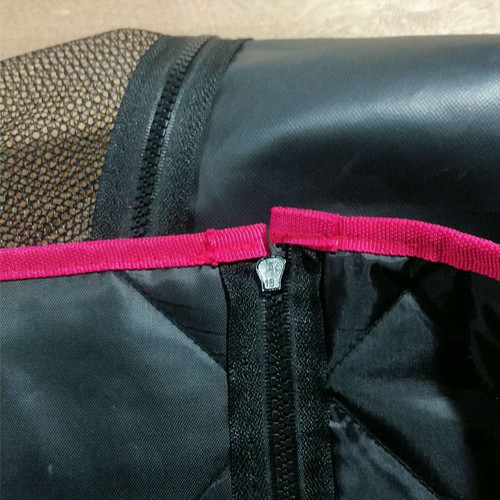

This is particularly evident in Textile manufacturing. A lot of manual work is usually involved in the process, leading to such common handmade production defects as skipped and irregular stitching, uncut threads, loose buttons, and so on.

In case such flaws are found in the course of inspection and the client considers the defect rate to be too high, the whole batch may be returned to the supplier for corrections.

Quantity of inspected items

The percentage of inspected items is determined by AQL standards and depends on the following factors:

- Total quantity of the items in the batch.

- Technical complexity of the items.

For example, the inspections of consumer electronics are usually more time-consuming because the inspector has to test functionality of the items in addition to the examination for external defects and overall quality.

Normally we aim to inspect 5-10% of the total amount of the goods.

Does it make sense to perform rejection of every item during the inspection?

We do not recommend asking the inspector to perform rejection of every item.

Firstly, this is usually impossible time wise in the course of one inspection and may require additional visits to the factory. Such approach only makes the inspection more expensive and delays shipment.

Secondly, it only leads to even higher defect rates in future orders. The supplier gets the idea that the rejection is taken over by an inspection company, whereas it is the function of internal quality control department.

The main purpose of a pre-shipment inspection is to identify potential problems with the goods and provide accurate data about it, so that the supplier could address them.

More topics on Quality Control Inspection services

The role of Quality Control in a successful product launch on Amazon

“What you see is what you get”: how to get positive reviews on Amazon for the new product launch? Product quality and customer satisfaction are the key elements for a successful product launch on Amazon. How can LIVE product inspections help you with that? Quality...

LIVE Quality Control Inspection in China

LIVE pre-shipment inspection - Innovative solution for Amazon sellers LIVE Quality Control inspection in China: Respond quickly to any problem with your goods and correct the defects on site. FBAHELP provides quality control inspections in China in LIVE Mode. This...

Mobile accessories inspection in China

Quality control inspection services by FBAHELPFBAHELP provides quality control inspection service of a wide range of products in China, including Mobile accessories .Mobile accessories inspection often requires the use special equipment. If the factory does not...

Cargo insurance for Amazon FBA shipments

Extended Liability Coverage FBAHELP offers cargo insurance for Amazon FBA shipments against damage or loss of the goods - extended liability coverage International cargo delivery is a complex process, requiring concerted efforts of all the involved parties. Errors on...

Factory audit in China in LIVE format

Factory audit - one of the crucial steps of searching for suppliers FBAHELP conducts factory audits in China in LIVE format. You will be able to communicate with the inspector and receive all audio, photo and video data in real-time. For any Amazon vendor it is...